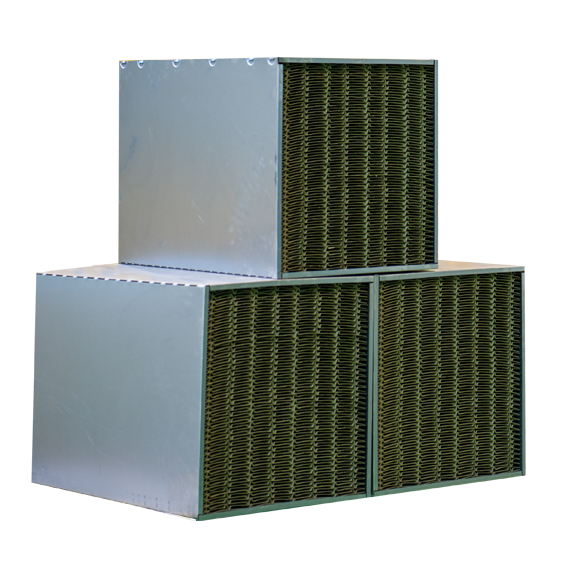

SCR catalyst is a key technology to reduce nitrogenous compound

accounting for the largest part of air pollutants.

a technology in which NOX and NH3 are reduced to molecular nitrogen (N2) and molecular water vapor (H2O) by chemical reaction on the catalyst surface. This is a post-processing technology of the combustion process that can reduce nitrogen oxides (NOX) from combustion gases of fossil fuels such as coal, oil, and natural gas to less than 10%.

optimizes specifications and performance according

to customer site conditions.